Excellent protection performance

With good puncture performance, it can provide reliable protection for products and effectively avoid damage during transportation and storage.

Clean Packaging

It will not produce debris and breakage in the process of use, ensuring a clean packaging environment, especially suitable for packaging of products with stringent requirements on hygiene conditions, such as electronic components, precision instruments and so on.

Excellent lubrication and friction reduction

The self-lubricating characteristics of the surface layer can reduce the friction between the packaged items and prevent scratches or damage due to friction, which is of great significance for products with high surface accuracy requirements, such as automotive parts, handicrafts and so on.

Good fusing performance and low water vapor transmission rate

Its excellent fusing performance ensures the sealing of the package, coupled with a low water vapor transmission rate, can effectively prevent external water vapor from entering the package, thus providing a stable preservation environment for humidity-sensitive products, such as liquid crystal panels.

Widely used in liquid crystal panels, automobile parts, crafts packaging and other high-end packaging with special requirements, etc. It also plays an important role in the packaging of electrical appliances, product models, etc., providing a strong guarantee for the safe transportation and proper preservation of various products.

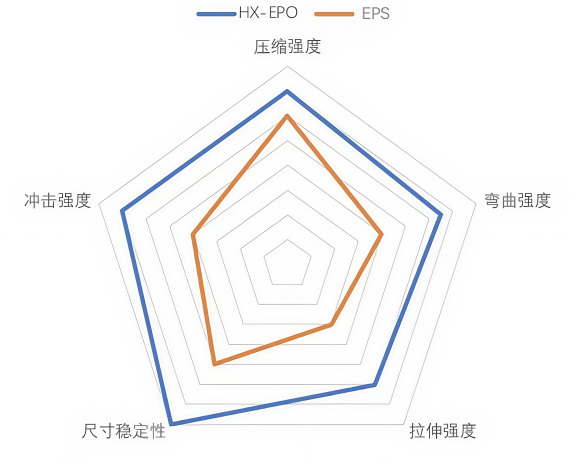

After performance test comparison, HX-EPO material is significantly better than traditional EPS material in key indicators such as compression strength, impact strength, bending strength, dimensional stability and tensile strength.